Austek-Carbon-Assessment-Summary-2020.10.29.pdf

Carbon assessment by RPS Strategy & Investment

Increasing demand for asphalt presents environmental challenges, but also opportunities

Recent growth in major road infrastructure across Australia has underpinned the increasing demand for asphalt. This demand is predicted to continue into the immediate future as government looks to stimulate the economy through further investment in large-scale infrastructure projects.

The key greenhouse gas (GHG) emission sources from asphalt production are liquid fuel combustion, transport, and embodied emissions in fuel and bitumen.

Reducing GHG emissions from this widely used construction material can make a strong contribution to meeting Australia’s climate change mitigation goals.

GHG emission reductions from Austek Asphalt’s Yatala production plant

Emission reductions from Austek Asphalt Services facility on the Gold Coast

Austek Asphalt Services (Austek) is an Australian company who have developed a production facility designed to reduce the carbon intensity of asphalt production.

RPS undertook a carbon assessment to estimate the GHG emissions reduced by this facility, relative to a typical (benchmark) Australian asphalt plant, which showed that:

A facility that produces 160,000 tonnes per year of asphalt is estimated to:

- Reduce annual GHG emissions by 6,800 tonnes of CO2-e.

- Divert 1.6 million car tyres from landfill (or 10 tyres for every tonne of asphalt produced).

6,800 tonnes of CO2-e is equivalent to the amount of GHG emissions reduced by taking around 3,100 cars off the road.

Broader environmental and economic benefits

Compared to a benchmark plant, Austek’s Yatala plant will require less production of virgin resources including diesel, bitumen and quarry material.

Beyond avoiding GHG emissions, this also avoids resource depletion, and land and amenity impacts from mining.

The use of locally produced tyre derived fuel, carbon char, recycled plastic and recycled glass also retains more economic activity within the region and reduces imports.

Using recycled inputs avoids broader environmental and resource depletion impacts, and using locally produced materials supports regional economic activity and employment.

How Austek reduces emissions

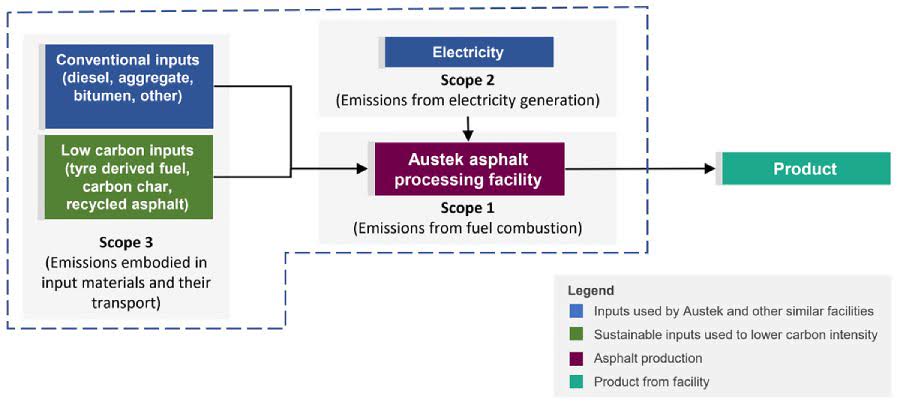

Austek’s asphalt production process

RPS modelled Austek’s operation that will process virgin material from an adjacent quarry site, carbon char, reclaimed road pavement (RAP), recycled glass and plastics, lime and bitumen to produce around 160,000 tonnes of asphalt per year.

The facility uses tyre derived fuel (TDF), a more sustainable fuel source, in place diesel. The TDF is more energy dense, improves fuel economy, and has much lower embodied emissions compared to diesel. The use of recycled plastic and glass also avoids embodied emissions from using virgin bitumen and sand. The Austek plant will also use a warm mix process for 63% of its production, which further reduces fuel consumption.

The tyre derived fuel and carbon char are sourced from Pearl Global, a nearby tyre recycling facility.

By using tyre derived fuel, carbon char and reclaimed road pavement, Austek avoids the energy, GHG emissions and other environmental impacts from producing virgin material substitutes including diesel, bitumen and aggregate. Testing by Queensland Transport and Main Roads (TMR) has also found beneficial performance properties of the product, including reduced Marshall Flow (increased strength).

Alignment with circular economy initiatives

Austek’s activities strongly align with circular economy objectives, which include maximising the value of resource use while minimising environmental impacts.

Encouraging circular approaches has become a crucial issue for Australian federal, state and local governments because of the increased pressure on our scarce resources, a tightening of waste export markets, and public concerns about climate change and the state of the environment.

RESULTS AND TECHNICAL INFORMATION

Methodology

The carbon assessment was conducted in accordance with The Greenhouse Gas Protocol: A Corporate Accounting and Reporting Standard (World Business Council for Sustainable Development and World Resources Institute, 2015)

The assessment compares the GHG emissions from the Austek plant’s and a Benchmark Plant’s activities. The difference between the Austek Plant scenario (i.e. the emissions from making the asphalt using Austek’s process) and the Benchmark Plant scenario (i.e. the emissions from making asphalt from a typical facility) represents the emissions saving.

The methodology involves:

- Defining the system boundary (see previous page)

- Selecting emission sources to be included in the assessment

- Estimating the quantities of inputs and emission factors associated with their use (refer to the next page)

- Calculating total emissions from the sources

- Comparing the total emissions of the Austek plant to the Benchmark Plant

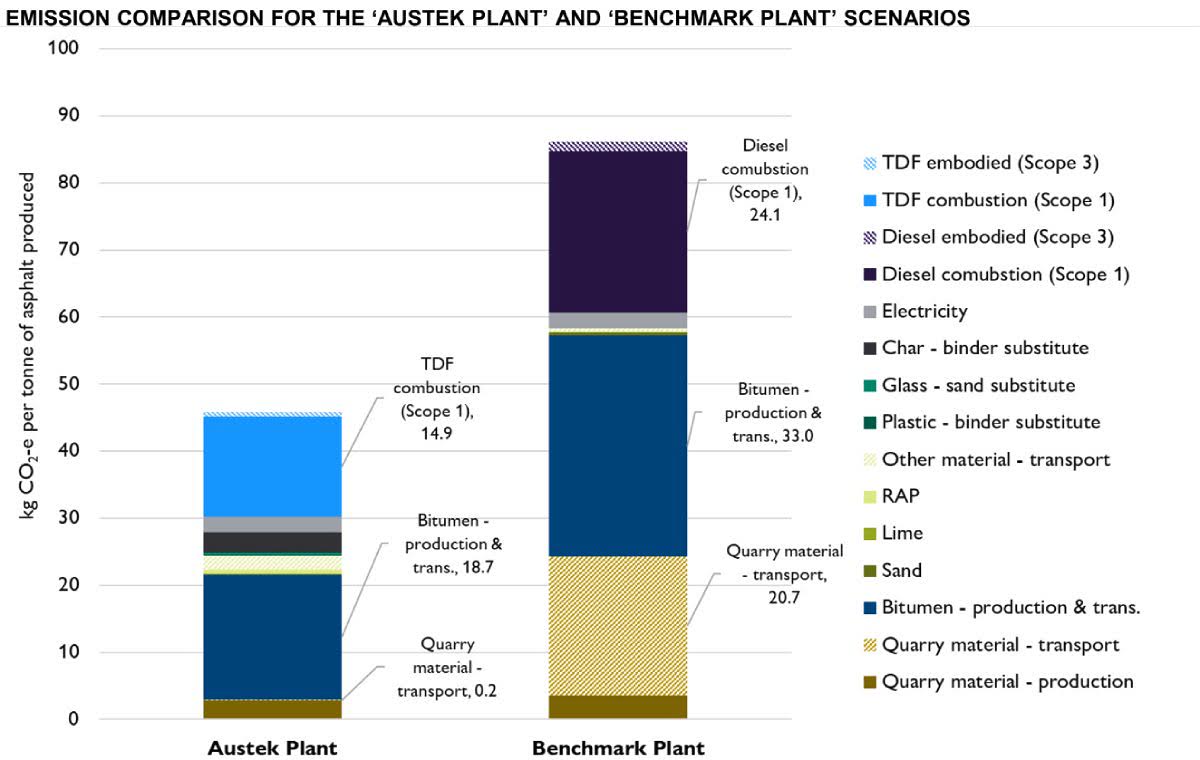

The results show an estimated 48% reduction in emissions from the Austek plant, which means that for every tonne of asphalt produced, 42 kgCO2-e are saved from being emitted into the atmosphere and 6,800 tCO2-e are saved over the year (equivalent to taking 3,100 cars off the road).

The process will also result in the diversion of 1.6 million car tyres from landfill (or 10 tyres for every tonne of asphalt produced).

Assumptions and sources

The table below provides the estimated unit emissions (kgCO2-e per tonne of asphalt production) for each input into the Austek and the Benchmark plant.

| Emissions source | Scope | Austek | Benchmark | Comment |

|---|---|---|---|---|

| Quarry material – production | 3 | 2.8 | 3.5 | |

| Quarry material – transport | 3 | 0.2 | 20.7 | |

| Other material – transport | 3 | 2.1 | 0.4 | |

| Bitumen – production & transport | 3 | 18.7 | 33.0 | Bitumen use reduced through the use of additives, plastic and carbon char |

| Sand | 3 | 0.0 | 0.5 | |

| Lime | 3 | 0.0 | 0.0 | |

| Reclaimed Asphalt Pavement | 3 | 0.6 | 0.2 | Greater use of RAP avoids emissions and other environmental impacts |

| Plastic – binder substitute | 3 | 0.1 | 0.0 | Reduces bitumen use |

| Glass – sand substitute | 3 | 0.3 | 0.0 | Avoids emissions and other environmental impacts |

| Char – binder substitute | 3 | 3.0 | 0.0 | |

| Electricity | 2 | 2.4 | 2.4 | |

| Diesel combustion | 1 | 0.0 | 24.1 | |

| Diesel embodied | 3 | 0.0 | 3.5 | |

| TDF combustion | 1 | 14.9 | 0.0 | Lower fuel consumption due to higher energy density and warm mix configuration |

| TDF embodied | 3 | 0.6 | 0.0 | Embodied emissions in TDF much lower than in diesel production |

Key sources used in the assessment were:

- RSK (2009). Synthetic fuel manufacture: Proof of Concept LCA. Australian Renewable Energy Agency (ARENA)

- RPS Group (2019). Pearl Global Greenhouse-gas Lifecycle Emissions Assessment.

- Meddah, M. S. (2017). Recycled aggregates in concrete production: engineering properties and environmental impact. In MATEC Web of Conferences (Vol. 101, p. 05021). EDP Sciences.

- Gibson, S., & Strachan, P. (2011). Reducing the embodied carbon content of asphalt.

- Masnadi, M. S. et al (2018). Global carbon intensity of crude oil production. Science, 361(6405), 851-853.

- Warnken ISE (2016). Carbon Value Proposition: Resource Recovery using Tyre Derived Fuel (TDF).

- Al Adday, F. (2019). Study of reducing the environmental impact of CO2 emissions of flexible pavement materials: a critical review. International Journal of Development Research, 9(04), 26883-26889.

- Department of the Environment and Energy (2019). National Greenhouse Accounts Factors. Canberra: Commonwealth of Australia.